July 2011, Vol. 66 No. 7

Features

Fort Worth Launches Unique, Aggressive Sewer Inspection/Cleaning Program

The city of Fort Worth, TX, sanitary sewer system serves 22 communities with a total population of more than 900,000. It contains approximately 3,011 miles of underground pipe infrastructure that collects and carries an average of 108.5 million gallons a day to the Village Creek Water Reclamation Facility.

As with all cities, maintaining sewer infrastructure is a never-ending and costly task. One key to keep piping in good condition is acquiring and analyzing accurate data about its condition in order to anticipate potential problems and address them in a timely manner.

To accomplish this, Fort Worth is committed to a multiyear inspection program for all sanitary sewer lines of 24 inches in diameter and larger. However, Fort Worth’s approach to inspections is different than typical programs which clean sections of pipe, then conduct inspections with closed-circuit television (CCTV) cameras.

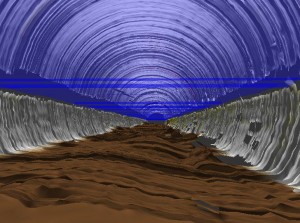

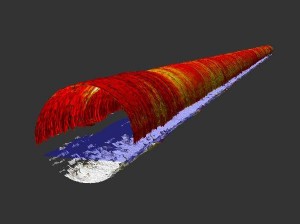

The city has reversed the process, inspecting pipes before cleaning. Fort Worth’s inspection process for large-diameter sewer pipes is more comprehensive than simply using CCTV video; instead, it employs high-definition video, laser profiling and sonar, then cleans only segments needing attention.

To implement these assessment technologies, the Fort Worth Water Department (FWWD) developed and initiated the Interceptor Condition Assessment Program (ICAP). Under the program, the city has committed to a multiyear plan to inspect all of the sanitary sewers that are 24-inches in diameter or larger.

Inspection

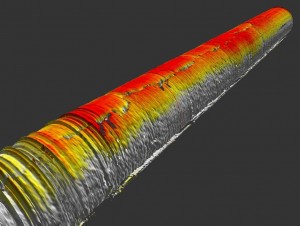

Darrell Gadberry, FWWD field operations division regulatory and environmental coordinator, said conventional CCTV inspections can identify defects such as cracks, breaks and roots, but does not provide a means of evaluating the severity of wall loss due to corrosion. To do that, the only option has been to excavate, take core samples, repair the pipe and restore the site, a costly and time-consuming process.

“The recent introduction of 3-D laser technology for large-diameter sewers demonstrated the ability to solve this problem,” he explained. “Coupled with high definition television (HDTV) inspection and gathering sonar data, the FWWD recognized ways to overcome the inefficiencies associated with the conventional approach used throughout the industry for assessing large-diameter sewer pipes.”

FWWD’s inspection contract uses the Fly-Eye HD Profiler System developed by Cleanflow Systems in New Zealand and distributed in the United States as the Fly-Eye Pipeline Inspection System by CUES. The inspection system collects and processes data on internal pipeline conditions including debris level, ovality, H2S erosion, lateral location and damage without requiring flow diversion, flow interruption or manhole ring removal.

“Currently only four units exist,” said Gadberry, “and two are deployed in Fort Worth. This technology assimilates a huge dataset for condition assessment. However, the primary goal is to identify lines for cleaning, hence the cost effective ‘inspect-before-cleaning approach’.”

Cleaning

Ace Pipe Cleaning Inc./Carylon Corporation has the contract for cleaning pipe identified during the inspection process. Various technologies are used, depending on cleaning requirements, including high-velocity and power-driven buckets and scrapers.

“Over the course of implementing our sewer assessment program,” said Gadberry, “we discovered that the clean-and-inspect methodology used for smaller-diameter pipes did not fare well for our larger pipes. The cost to clean big pipes is expensive, ranging from $3 to $40 per linear foot. Add in the cost for debris disposal, by-pass pumping, CCTV inspection and other essentials, and wise choices are necessary when dealing with big pipes.”

Making inspections before cleaning showed debris in large pipes has a tendency to build up at junction structures and in the connecting pipes, then quickly dropped off a short distance outside the structure. The inspections have allowed cleaning to target areas where it is needed.

Gadberry said that by inspecting before cleaning, it was estimated that cleaning costs of large-diameter pipes can be reduced as much as 30 percent.

“To date,” he continued, “approximately 187,000 feet of pipe has been inspected of which 75,000 feet required cleaning. At a total cost of $1.23 million, this represents an approximate cost savings of 36 percent over the conventional clean and inspect approach — $1.23 million versus $1.91 million. This is a very cost-effective approach, especially when savings are projected over the one million feet of large-diameter interceptors within the FWWD’s collection system.”

Post-cleaning sonar inspections have substituted for post-cleaning CCTV inspections to confirm the cleanliness of the pipe.

Program management

Gadberry said the third and most important facet of the ICAP is program management. All information gathered is assembled into a mosaic image of the system’s sewer interceptors for analysis of the data and to use in making recommendations, including an estimate of the remaining useful life of each pipe.

White Rock Consultants and sub-consultant Freese Nichols Inc. were selected to manage the project.

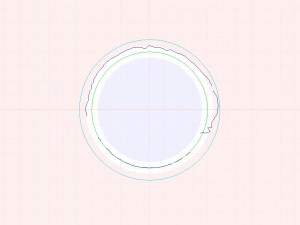

In order to take full advantage of this technology, specific information is needed. Pipe material, wall thickness and location of steel placement is critical and should be made available prior to post processing the field data. Once the 3-D rendering has been completed, the dataset will contain accurate measurements of wall loss due to deterioration and/or corrosion.

“Laser data is used to measure and visualize the inside profile of the pipe,” said Rod Thornhill, president of White Rock Consultants. “This identifies pipes with wall loss from corrosion, pipes that are out of round (deflection or deformation), and measures the true inside diameter of the pipe. The sonar measures and profiles the amount of debris below the water flowline and is the primary tool used to select pipes for follow-up cleaning.”

FWWD utilizes a pipe television inspection software application from Infrastructure Technologies (IT). Under the ICAP program, a conversion application was developed to merge the 3-D laser, sonar and HDTV data, videos, pictures and observations into the existing inspection database. All the pipe material and hydraulic model data is pre-populated into each inspection record using the IT pipe GIS SendIT module. The modeled wet/dry weather average depth and wet/dry weather maximum depth are incorporated into the dataset for evaluation during the review process.

The typical deliverable of a 3-D laser, sonar and HDTV inspection is a printed PDF report. However, Gadberry said the FWWD has elected to maintain the inspection records digitally which allows multiple inspections of a single asset to be compared over time.

“The ability to compare pipe wall deterioration over the years will be extremely valuable when estimating the remaining useful life of our assets,” he explained

Thornhill said one interesting aspect of the project was that early inspection data identified many pipe sections where the dry weather flow significantly differed from the dry weather flow predicted by the model.

“Freese Nichols,” he said, “recently developed the wastewater collection system model as part of the Wastewater Master Plan. Since they were part of the engineering team we were able to identify where the model data required additional review and make any corrections to the model, if necessary.”

Program accomplishments, expectations

“The ICAP program,” said Gadberry, “has allowed the FWWD to identify locations of probable failure and replace or rehabilitate the pipe before failure actually occurs. The cost to replace or rehabilitate a large diameter pipe before it collapses is a fraction of the cost to address pipe failure after it occurs. Eliminating SSOs before they occur, avoiding catastrophic environmental impacts, and keeping our large diameter interceptors at their peak designed performance and structurally sound makes ICAP an extremely cost-effective program.”

If funding permits, Gadberry said the FWWD has a seven year goal to inspect 100 percent of all pipe 24-inches and larger.

FOR MORE INFORMATION:

CUES, (800) 327-7791, www.cuesinc.com

Ace Pipe Cleaning/Carylon Corporation, (800) 621-4342, www.caryloncorp.com

White Rock Consultants, (214) 725-8976, www.whiterockconsultants.com

Comments