April 2012, Vol. 67 No. 4

Features

Unique Solution To Manhole Installations In Busy Chicago Intersections

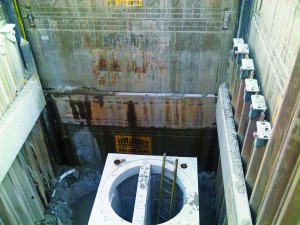

DiPaolo Construction, of Calumet City, IL, recently completed a $14 million underground utility project to install personnel access manhole structures over an existing combined storm/sanitary sewer line in the South Chicago community of Hegewisch.

The project was challenging in that the manholes needed to be installed in the middle of two different intersections. One of those locations was a major thoroughfare with bus routes, requiring DiPaolo to keep one lane of traffic moving in each direction.

The second major challenge was finding a solution for safely shoring the 18 by 24-foot wide, 24-foot deep excavation while disrupting the intersections as little as possible. Traditional means of shoring such as trench boxes were immediately ruled out. It was not possible to over-excavate enough to install trench shields and still keep traffic moving. Sheeting is usually the first alternative to trench shields, but vibrating sheeting into place was also not possible because of the potential to disturb or undermine the adjacent road and buildings.

DiPaolo needed an active shoring system which maintains pressure against the soil at all times, does not require extra equipment or over-excavation, and most importantly, could keep workers safe throughout the entire excavation and underground utility installation process.

After some research, DiPaolo found an alternate shoring option that met all safety and excavation requirements: a Slide Rail Shoring System from Efficiency Production Inc. But the slide rail solution also came with a new set of challenges, that of the bureaucratic variety.

Proof

“The city of Chicago’s Department of Water Management was not at all familiar with slide rail, and they wanted to see every type of documentation on every part of the system before their engineers would approve it,” explained Sal DiPaolo, vice president of DiPaolo Construction. “Engineering notes, calculations, 3D CAD drawings, installation instructions were requested — fortunately all of which Efficiency was able to provide.”

Slide rail is considered “active shoring,” installed by sliding the panels into integrated rails on the posts, and then pushing the panels and posts incrementally down to grade as the pit is dug — a process commonly referred to as a “dig and push” shoring system.

DiPaolo rented a modified four-sided pit system that utilized two Efficiency Shore-Trak panel guides. The panel guides replace regular slide rail panels which allowed DiPaolo to install stab sheeting tightly around the existing sewer line on both ends, 12 feet into the excavation. Shore-Trak panel guides are an exclusive feature of Efficiency Production’s Slide Rail System.

Once the existing and active 72-inch combination sewer was uncovered and excavated below the pipe’s invert, DiPaolo cut open a large section of the pipe and inserted two 16 inch HDPE lines, creating a flume that kept the water flowing and the pipe active. DiPaolo installed a precast 9.5 by 17-foot manhole base structure in the open section, with a second structure on top of the base that transitioned to an eight-foot diameter round manhole with access from the road.

This entire process was repeated again in the middle of another intersection, utilizing the same slide rail components.

Regarding Slide Rail, Sal DiPaolo concluded: “I thought it was a great approach for the unusual challenges of this particular project. I’d certainly use it again in the future, if it seemed like the right application for the project.”

Founded by Angelo DiPaolo in 1960, DiPaolo Construction is a 50-year-old, family-owned company. Angelo DiPaolo is a past president of the National Utility Contractors Association.

Efficiency Production Inc. provides a wide selection of standard and custom trench shielding and shoring systems.

FOR MORE INFO:

Effiency Production, (800) 552-8800, www.efficiencyproduction.com

Comments