June 2015, Vol. 70, No.6

Features

TTC Auger Boring and Pipe Jacking School

Trenchless technology and open-cut construction can be fulfilled by increasing the demand for underground construction.

Trenchless technology is an economical and convenient alternative to open-cut construction when it is employed appropriately (Atalah, 2007). “Trenchless technology includes techniques for utility line installation, replacement, rehabilitation, renovation, repair, inspection, location and leak detection, with minimum excavation from the ground surface” (NASTT).

History

“Like most other construction equipment, the horizontal auger boring (HAB) machine was developed because of market demand. As early as 1936, the first boring machines were made from rear ends of old trucks. These machines were first built by CRC-Evans Pipeline International. The horizontal auger boring method was formally developed in the 1940s by Vin Carthy, Salem Tool Company, and Charlie Kandal.

In the 1940s, Charlie Kandal founded the Ka-Mo company, which manufactured the Ka-Mo horizontal auger boring machines. The initial machines were powered with electricity, but later models were gasoline powered. Salem Tool Company and Ka-Mo dominated the horizontal earth boring (HEB) business until 1961, when pipeline welder Al Richmond also started manufacturing small HEB machines. Until 1967, Richmond machines used Ka-Mo augers and cutter heads. He then built his own auger and cutter heads, which were similar to those of Ka-Mo. Richmond continued making advances in the equipment design to keep pace with the changing market. Roy Woodruff and Son designed the split machine and also put a spacer in the 36-inch machine to make it a 48-inch machine.

In the 1960s, Ernie Coppica, Wixom and Michigan invented a steering system. In 1970, Leo Barbera left Richmond Manufacturing and founded American Augers. American Augers started by building hydrostatic drive machines with a built-in slip clutch.” (ASCE Manuals and Reports on Engineering NO. 106. Horizontal Auger Boring Projects, 2004).

The Trenchless Technology Center (TTC) at Louisiana Tech University was established by Dr. Tom Iseley in 1989. It was created to promote research, development and technology transfer in the trenchless technology industry. The TTC is a cooperative research center for academia, government and industry, and has world-class research and testing facilities at the National Trenchless Technology Research Facility (NTTRF) in South Campus at Louisiana Tech. Dr. Iseley came back to the TTC as director after 20 years. “I am incredibly excited to be returning to the Trenchless Technology Center (TTC),” Iseley said.

For helping the industry and meeting the market demand, TTC is developing the Auger Boring & Pipe Jacking School (ABPJ) for educating contractors, engineers, managers, foremen and public utility personnel. The first school program will be October 12-16, 2015 at the TTC research facility in Ruston, LA.

Committee members for developing the ABPJ School program are: Leo Barbera (Horizontal Holes), Vic Weston (Tri-State Road Boring), Dan Liotti (Midwest Mole Inc.), Frank Canon (Baroid Industrial Drilling Products), Dan Heath and Mike Varone (American Augers Inc.), Maynard Akkerman, (Akkerman), Rick Barbera (Tri-State Trenchless), Johnny Britt (Thompson Pump), and Robert Carpenter (Underground Construction magazine).

The school will consist of classroom lectures (modules) and practical sessions held in the laboratory and in the field. There will be five modules and four practical sessions. The program schedule will be offered in two sections, Section A and Section B, each with about 25 students. Practical sessions will be held in designated LA Tech labs and in the field testing site at South Campus, located behind the TTC NTTRC facility (Fig. 1).

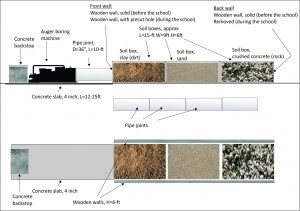

The field operations will be performed above ground without excavating pits. The basic auger track (Fig. 2) will have a concrete slab, approximately four-inches thick and 12 to 25-feet long, to hold the auger boring machine. A concrete backstop block will be built on one side to anchor the machine. Three soil boxes will be built on the opposite side, each approximately 15-feet long and 6-feet high, using modular wooden panels, 8 feet by 2 feet. The front and back wall will be solid wooden walls. Each of the three soil boxes will be filled with a different soil type: clay (dirt), sand and rock (crushed concrete). The soil in the boxes will be left to settle for several months. In addition to basic augering, a large diameter augering will be taught. Fig. 3 shows the location of those field tracks. This field session will use an auger boring machine and an expander to install a large diameter pipe (72-inch). This track will be set up and built next to the basic augering track, as shown in Figure 3.

Program schedule (Section A and Session B)

Students will enroll in one of two sections, Section A or B. However, both sections will merge into Section A if less than 50 students enroll.

Table 1 shows the classroom lectures and practical sessions schedule for Section A. Each module taught in the morning will follow up with the corresponding afternoon activities in the lab/field. In other words, each module will be taught on the same day as the lab/field activity.

Table 2 shows the classroom lectures and practical sessions schedule for Section B. Two classroom modules will be taught on the first day, and practical sessions will start on the second day in the morning. Thereafter, each module taught in the afternoon will follow up with corresponding practical session on a different day. Classroom Lectures and Practical Session are defined in Table 3. For more information, go to the TTC website (http://ttc.latech.edu).

Comments