October 2015 Vol. 70 No. 10

Equipment Spotlight

Rehabilitation New Products

Hibbard Inshore

In the water and sewer industry, the aim at Hibbard Inshore is to provide their clients with solutions in areas where the local sewer camera companies may face constraints. They do this by offering a variety of solutions to address inspections in all of the conditions seen in the water and wastewater industries, such as full pipes, partially full pipes and dry pipes.

Hibbard Inshore carries swimming, floating and crawling vehicles with long tether reaches to address each of these situations. The aim being that Hibbard Inshore can provide inspection solutions for all of a municipality’s large sewer lines, including those with long distances between access points or siphon areas. Each of the vehicles can be fitted with a variety of sensors to collect the best possible data for owners and engineers to make decisions on remaining lifespan, as well as the prioritization of repairs or replacement. The collected data is coordinated and can be interfaced with city GIS database systems, as necessary, so the information is easily accessible for future reference and comparison. 248.745.8456, www.hibbardinshore.com

TRY TEK

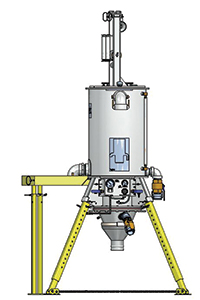

TRY TEK

TRY TEK’s Controlled Water Pressure (CWP) Inversion Unit is a product used to install pipe liner in the Cured-In-Place-Pipe (CIPP) method of rehabilitating pipe. Common methods of installing liner are to invert with air and cure with steam, or to invert and cure with cold and hot water. Air inversion units often contain the entire liner and have shorter run lengths. Water units often use a scaffold or lift truck to give enough head pressure to the water column.

The CWP Inversion Unit uses water pressure for inversion without the need of high scaffolds or lift trucks. Similar in design and size to an air inversion unit, the CWP Inversion Unit utilizes public water available from hydrants. A hot water boiler is then used to cure the liner. Throughout the inverting and curing processes, the CWP Inversion Unit is used to monitor and control the pressure.

The CWP Inversion Unit combines the benefits of water inversion with the convenience of air inversion. While this technology is not new, it was patent-protected from the open market until recently. TRY TEK Machine Works was the sole licensed manufacturer of this equipment until 1999. They are now able to offer this technology to the public. 717.428.1477, www.trytek.com

TT Technologies

Burst and replace water, sewer, gas and other pipes with the Grundoburst static pipe bursting system from TT Technologies. The Grundoburst can pull in a variety of replacement pipe including PVC, DIP, ABS, cast iron, fusion welded HDPE and VCP jacking pipe.

The Grundoburst static pipe bursting system utilizes a specially designed bladed cutter head to make bursting ductile iron and steel pipe possible. Pulled by a hydraulic bursting unit, the cutter head’s special cutting wheels split the host pipe. An attached expander spreads and displaces the split pipe into the surrounding soil while simultaneously pulling in the new pipe. Patented QuickLock bursting rods are linked together, not threaded. This saves time, prevents twisting and extends the life of the cutter head over threaded bursting rods. Six Grundoburst models are available for bursting 2-inch through 54-inch pipes and larger. 800.533.2078, www.tttechnologies.com

Madewell Products

Madewell Products

Madewell Products manufactures a variety of cementitious and epoxy products for the restoration and protection of structures such as brick and concrete manholes in the sanitary sewer market. Some of these products are combined to form the Mainstay Composite Liner. The Mainstay Composite Liner is a two-component system consisting of a high-strength restoration mortar, such as Mainstay ML-72 Microsilica Restoration Mortar and an epoxy corrosion barrier coating, such as Mainstay DS-4 or 5 Epoxy Coating. The latter cures simultaneously to repair and protect concrete and brick structures. The mortar is first shot onto a new or deteriorated substrate, and an epoxy topcoat is then immediately applied while the mortar is still soft. 800.741.8199, www.madewell.net

Source One Environmental

Source One Environmental (S1E) has announced a new product offering, the SilverBack XL, designed for pipe bursting and ramming applications. An extended flexible coupling, the SilverBack XL is a trenchless product that will serve as a useful tool for municipalities and underground contractors to create permanent, strong pipe connections.

As costly excavations become more obsolete, underground utilities agree that pipe bursting and ramming are effective trenchless solutions to repair failing pipe. Specifically for pipe bursting and ramming, the SilverBack XL allows contractors to easily connect the two pipes together without having to worry about soil conditions or tensile stressing altering the pipes’ structural integrity. Engineered to be stronger, longer and more durable than any coupling in the market. 810.412.4740, www.s1eonline.com

Comments